Rapid PCB Prototyping

What Is Rapid PCB Prototyping?

Rapid PCB prototyping is the pre-production of printed circuit boards before mass production, usually requiring PCB prototype manufacturers to quickly produce 5 to 100 pieces to help speed up the design and testing process. It is mainly used for electronic engineers to deliver the designed PCB files and BOM to the manufacturer after they have completed the circuit board. It needs to be analyzed from multiple perspectives to ensure that there is no delay in the project cycle and reduce the risk of product release.

What Are the Benefits of A Rapid PCB Prototyping?

Fast turnaround

Product testing

Modification flexibility

Cost reduction

How to provide documents for rapid PCB prototyping

What should be noticed in the rapid pcb prototyping documentation?

- File format: Normally need to provide Altium/Gerber/Eagle files. For the Gerber file, (for now we only accept RS-274-X format), double layers are shown below:

GTL- top copper layer

GBL- bottom copper layer

GTS- top solder mask layer

GBS- bottom solder mask layer

GTO- top overlay layer

GBO- bottom overlay layer

DRL -drill layer

GM1- mechanical 1

GKO- keep-out layer

4 layers need the extra layer order, eg:

TOP-VCC-GND-BOT 、TOP-GP1-GP2-BOT、 TOP-G1-G2-BOT、 art001-art002-art003-art004

- PCB parameters: there are general the number of layers, material, thickness, surface finish, color of solder mask, copper thickness, and other specific requirements, the following to understand the main parameters of this part.

Materials:It is best to consult in advance to explain what kind of materials are required for the manufacture of rapid PCB prototyping. At present, the most common material is FR4, FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios.

Layers:The price of PCB board varies with the number of layers

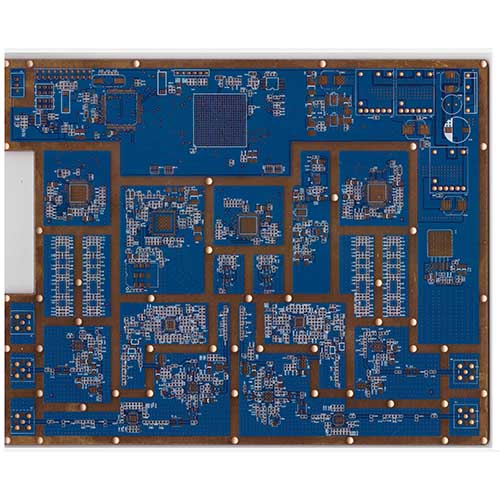

Solder Mask: There are many colors about rapid PCB prototyping, green, black, white, blue, red, yellow, matt black and matt green (We support all of the above color). It is worth mentioning that considering efficiency and cost, Kingda regards green as a conventional color.

Silkscreen: The silkscreens printed on the PCB is usually matched with the solder mask color.

Copper:Generally according to the current of PCB circuit to scientific calculation of the thickness of copper, generally the thicker the better, but the cost will be higher, so it needs a reasonable balance (we support 1 to 10oz).

Via Process:Tenting vias, Plugged vias and Vias not covered

Surface Finish:Currently we support Electroless Nickel Immersion Gold (ENIG), Hot Air Solder Level (HASL, Lead and Lead‐free), OSP, Immersion Tin, Immersion Silver, ENEPIG Gold Fingers, Flash Gold, Full Body Hard Gold, Wire Bondable Gold, etc.

Quantity: The number of PCB prototypes to be made must be clearly stated.

Other Special Requirements: if there are any other special requirements for PCB manufacturing, you should also inform to your PCB manufacturer, like impedance control, custom stack-up and other special production process.

How to choose A Rapid PCB prototyping manufacturer?

The functionality of Manufacturing Equipment

Assembly Staff Obligations

Quality Systems

Shipping Deadlines

Parts Procurement

Economical Pricing

About Kingda

Our PCBA Prototype Services

SMT and Through-Hole Assembly

Fine Pitch Component Insertion

4~7 Days Quick Turn rapid pcb prototyping

Parts Analysis, Selection and Procurement

Quick response for technical support

100% X-Ray & AOI Testing

IC Programming/ Functional Testing

Our PCBA Prototype Capabilities

| PCB Type | Rigid, flex, rigid-flex PCB |

|---|---|

| PCB thickness | 0.3mm–6mm |

| PCB Size | Max: 1200*600mm, Min: 50*50mm |

| Minimum SMD component | 01005, 0201 |

| Minimum BGA | 0.25mm pitch, QFN |

| IC Assembly Precision | ±0.03mm |

| Minimum Part Precision | ±0.04mm |

| Assembly Type | SMD, Through hole, Mixed Assembly |

| Soldering Type | RoHS & Lead-Free assembly |

| PCBA Production lines | 8 fully automatic production lines |

| PCBA Test | X-Ray & AOI, ICT & FCT, FAI Testing |

| Lead Time | Prototype: normal 2-3days (fastest expedited 12hours) |

| Low volume: normal 3-5days (fastest expedited 24-48hours) | |

| Volume production: 5-7days |

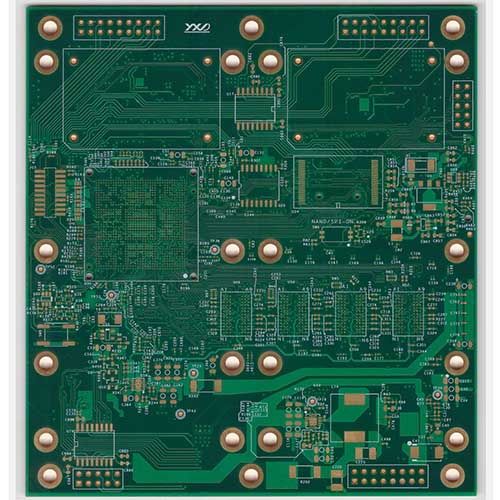

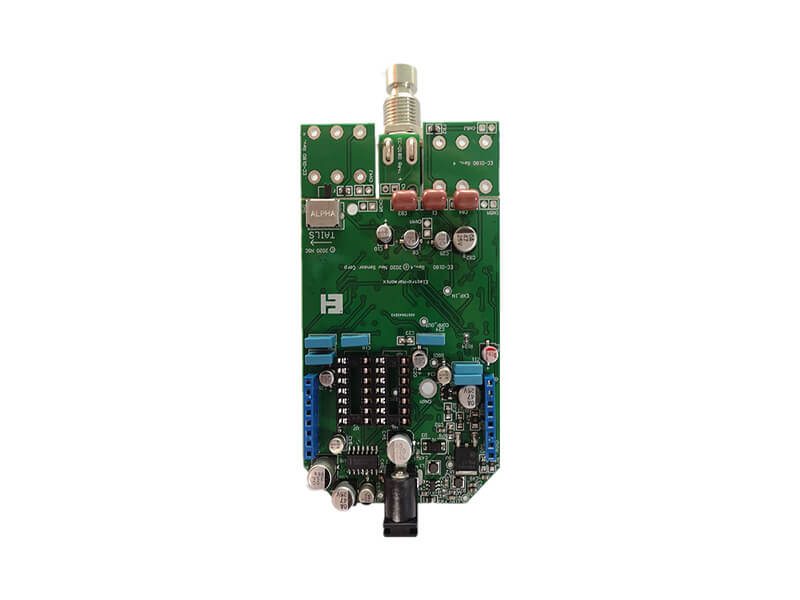

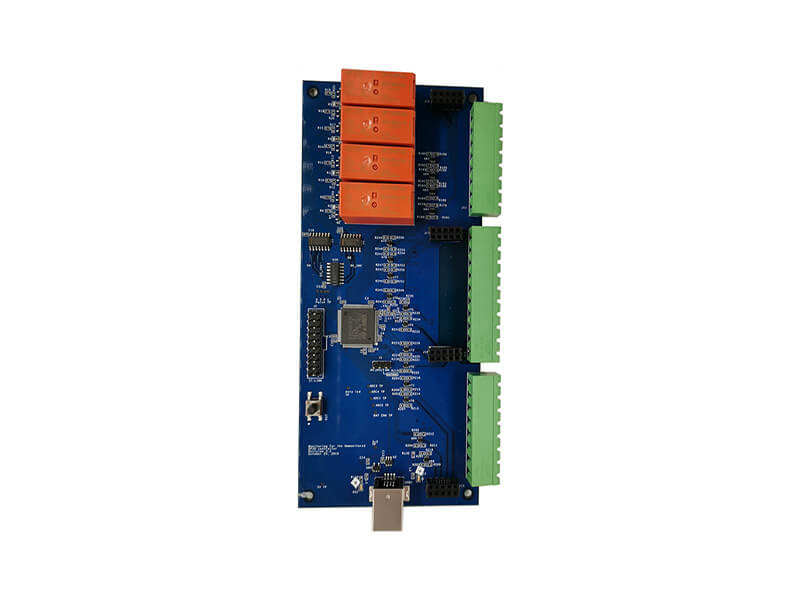

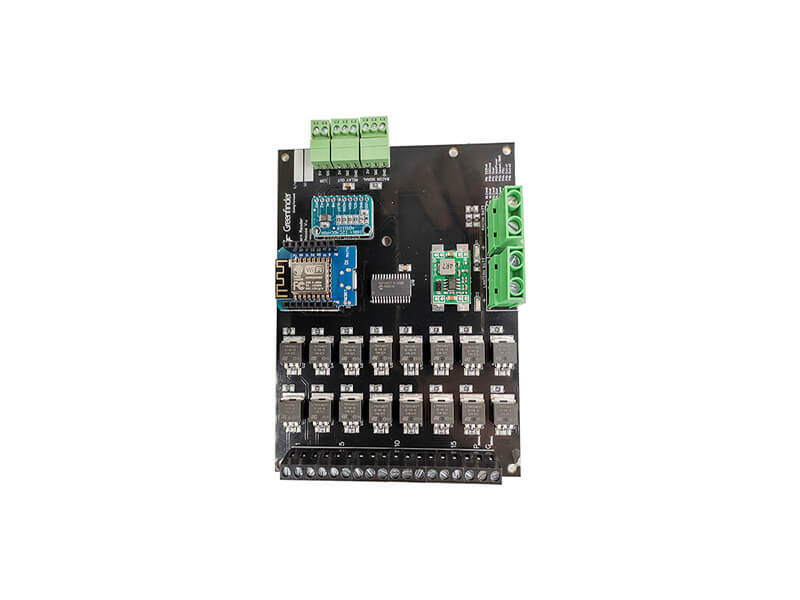

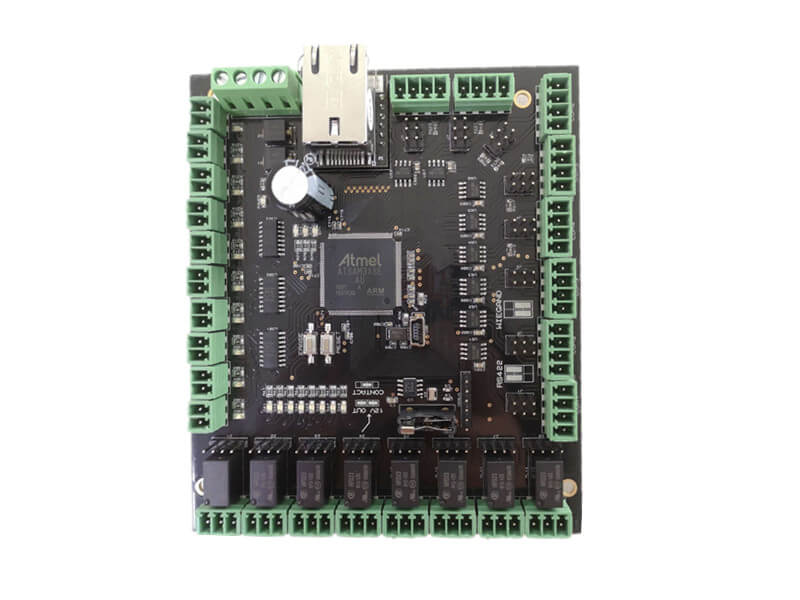

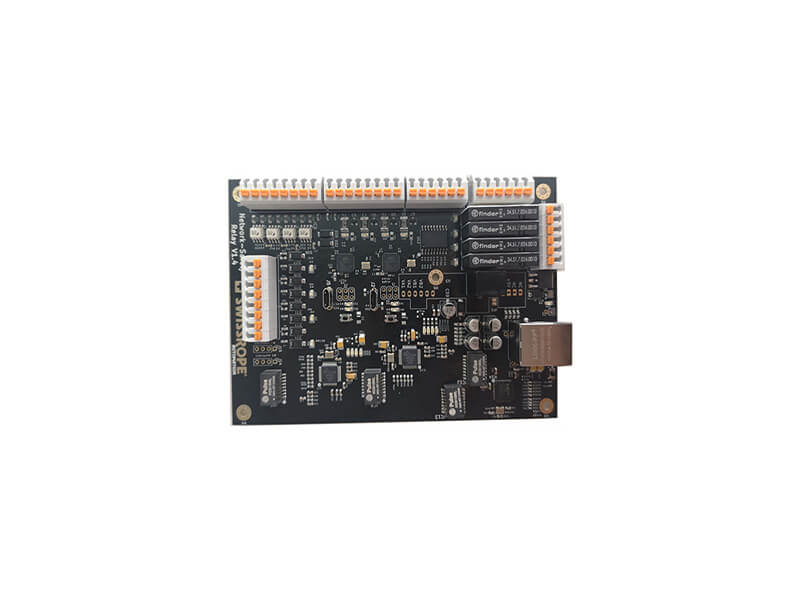

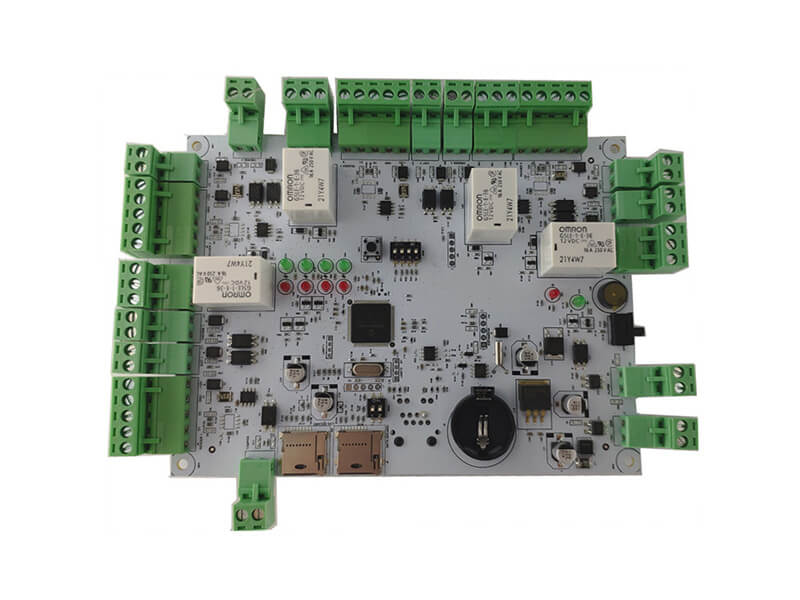

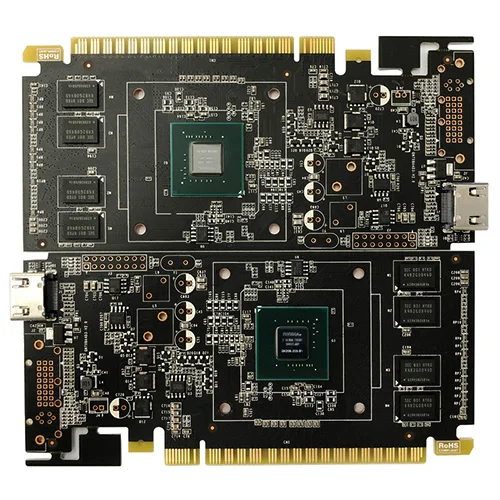

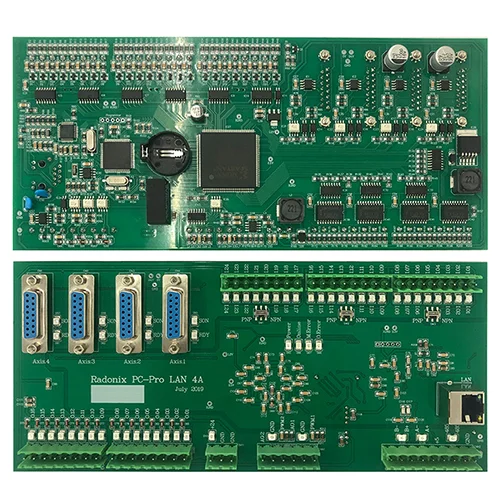

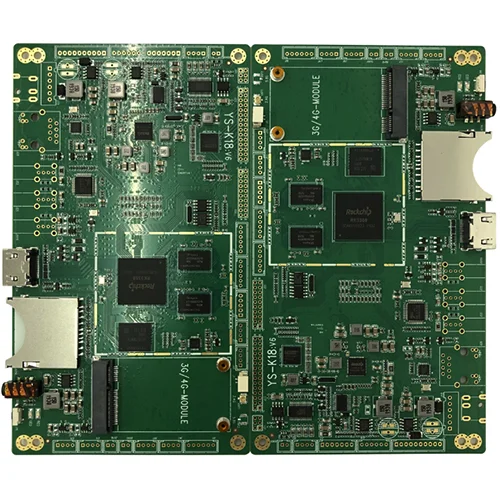

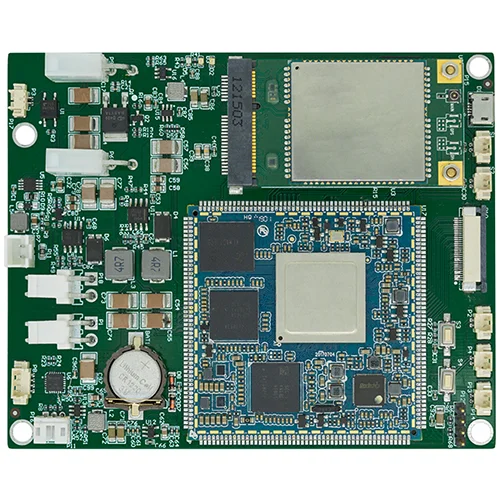

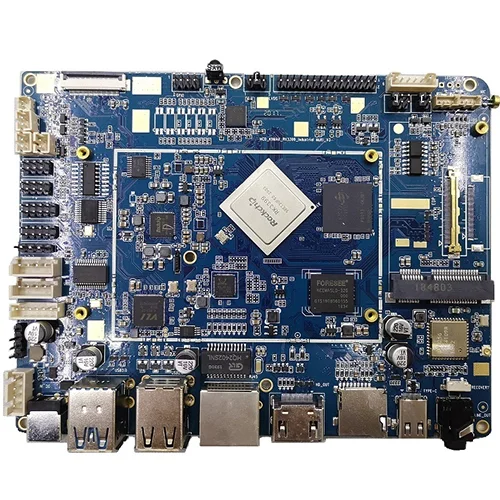

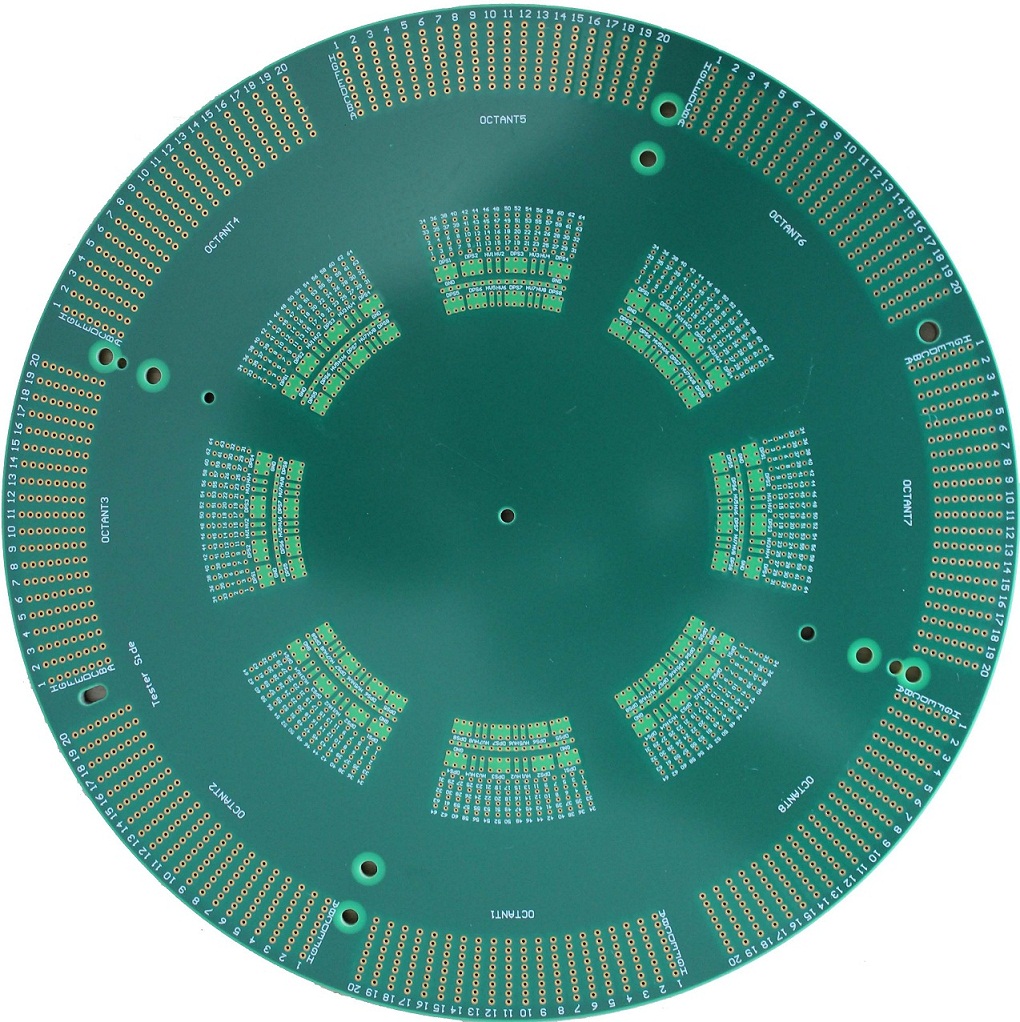

PCB and PCBA Product Showcase

SMT PCB Assembly

Medical Ventilator PCB Assembly

Through-Hole PCB Assembly

High Volume PCB Assembly

Prototype PCB Assembly

Turnkey PCB Assembly

10-Layer Hybrid PCB

12-Layer IC Test Board