In the field of electronics manufacturing and PCBA, Wave Soldering is a classic yet indispensable automated soldering technology. Especially when dealing with through-hole (THT) components that require high mechanical strength and power handling capabilities, wave soldering plays a critical role that directly impacts the durability and long-term reliability of the final product.

1. What is Wave Soldering?

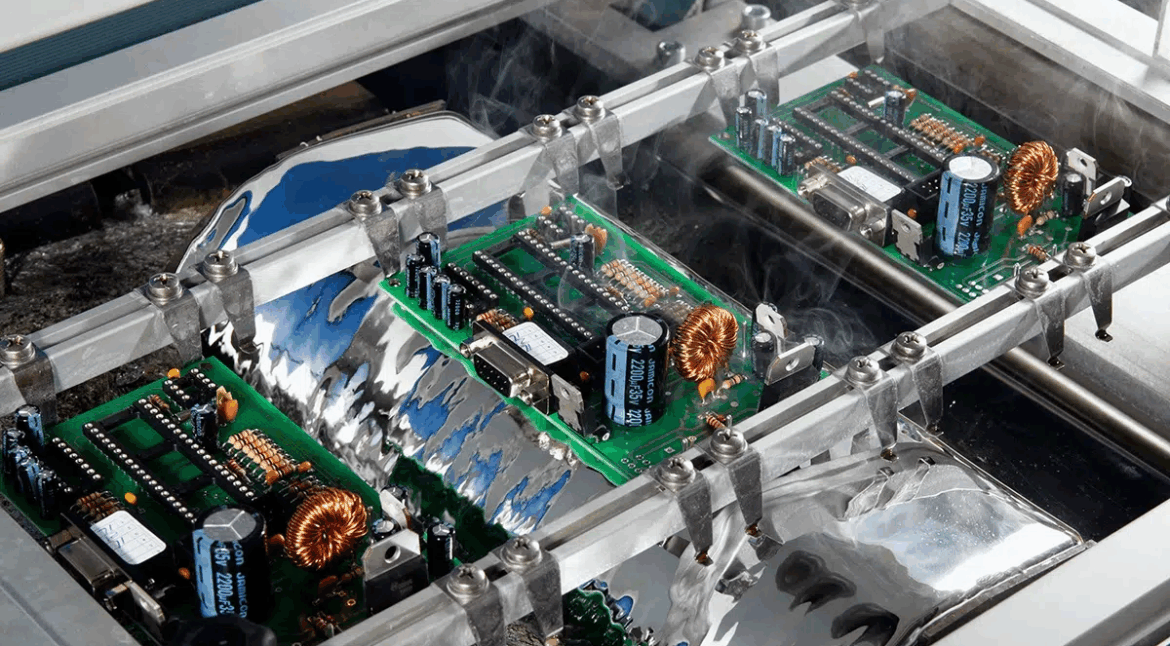

Wave Soldering is a bulk soldering process that uses a pump to force molten solder upwards, creating a “wave” of solder. When a printed circuit board (PCB) with inserted components passes over this wave at a specific angle and speed, the leads of the through-hole components and their corresponding pads are completely enveloped and soldered.

In simple terms, it’s like having the bottom of the circuit board efficiently and uniformly “surf” over a wave of liquid metal.

2. The Core Role of Wave Soldering in PCBA Production

In modern electronics manufacturing, especially for mixed-technology boards, wave soldering plays an irreplaceable role:

Provides Superior Mechanical Strength: Unlike SMT (Surface-Mount Technology) which forms a connection only on the surface, wave soldering fills the entire plated through-hole with molten solder, creating a 360-degree bond around the component lead. This robust, rivet-like connection provides unparalleled resistance to vibration and mechanical stress.

Handles High Power and High Current: Through-hole components (like large transformers, power transistors, and high-voltage capacitors) have larger leads that can handle far more current than SMT components. The full, thick solder joints created by wave soldering ensure these high-current paths have low resistance and high reliability, effectively preventing local overheating.

Enables Efficient Bulk Soldering: For circuit boards with a large number of through-hole components, wave soldering can complete all solder joints in a single pass. Its automated process dramatically increases production efficiency and reduces manufacturing costs, making it a key to cost-effective mass production.

Completes Mixed-Technology Assembly: The vast majority of today’s PCBAs contain both SMT and THT components. Wave soldering is the core process for completing the final soldering step on these “mixed-technology” boards. It is responsible for securely soldering all the THT components after the SMT components have been fixed in place via reflow soldering.

3. The Wave Soldering Process

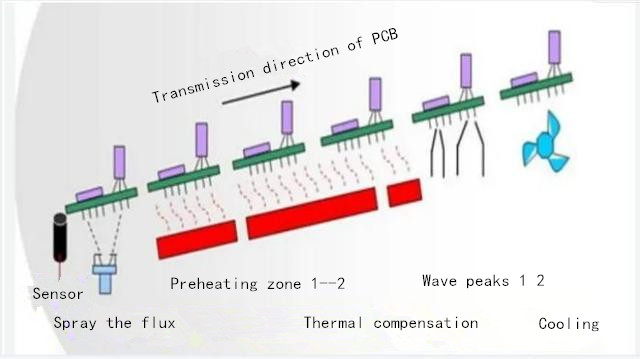

A standard wave soldering process is precise and rigorous, typically including these core steps:

Component Insertion: The leads of through-hole components (like connectors, capacitors, etc.) are inserted into their corresponding holes on the PCB.

Fluxing: A layer of flux is evenly applied to the bottom of the PCB to clean the metal surfaces and enhance solder wetting during the process.

Preheating: The board is slowly and uniformly heated to a set temperature to activate the flux and prevent thermal shock from the intense heat of the solder wave.

Wave Soldering: The key step. The bottom of the PCB makes contact with the molten solder wave. Modern machines often use a dual-wave system (a turbulent wave and a laminar wave) for optimal results.

Cooling: The cooling rate is controlled to allow the solder joints to form a good metallic crystal structure, ensuring their long-term reliability.

Conclusion

Wave soldering plays a vital role in PCBA production. It is not only an efficient method for the automated soldering of through-hole components but also a key guarantee for endowing electronic products with high mechanical strength and high power-handling capabilities.

Therefore, a deep understanding and precise control of every aspect of the wave soldering process are critical for improving the quality and performance of electronic products in high-reliability fields such as power supplies, industrial controls, automotive, and aerospace.

If your project requires high-reliability soldering of through-hole (THT) components, we are your ideal choice. We provide professional wave soldering services, utilizing modern equipment and strict process controls to meet your most demanding specifications.

Whether it’s for mixed-technology assembly, power electronics, or industrial controllers, we can guarantee superior joint strength and flawless quality. Please do not hesitate to contact our professional team to get the best solution and proposal for your PCBA project.