Engineering Context

As electronic systems are increasingly deployed in harsh and unpredictable environments, conformal coating has become a critical reliability-enabling process in modern PCB manufacturing. A properly selected and applied conformal coating protects printed circuit boards from moisture, chemical exposure, salt fog, vibration, and electrical stress while maintaining signal integrity and mechanical compliance. This engineer-oriented guide examines conformal coating technology from a materials science and process control perspective, covering coating chemistries, application techniques, thickness control, defect mechanisms, and environmental validation for industrial electronics, automotive, medical, aerospace, and RF PCB applications.

Core Engineering Challenges

Uncoated or poorly protected PCBs are vulnerable to corrosion, dendritic growth, leakage current, and premature electrical failure. These risks are amplified in high-density assemblies, fine-pitch layouts, and high-voltage or RF PCB designs, where reduced conductor spacing and elevated electric fields accelerate failure mechanisms.

Engineers must address several competing challenges when implementing conformal coating:

- Ensuring complete environmental protection without compromising phase stability or increasing insertion loss

- Achieving uniform coating thickness across complex 3D assemblies

- Preventing coating-induced defects such as dewetting, cracking, and voids

- Maintaining reworkability and inspection access

Effective conformal coating is therefore a controlled engineering process rather than a simple finishing step.

Material Science & Dielectric Performance

Conformal coatings are typically based on polymeric resins formulated to balance dielectric strength, mechanical flexibility, chemical resistance, and process compatibility. The selection of coating material directly affects insulation performance, EMI behavior, and long-term reliability.

Common Conformal Coating Materials

| Coating Type | Key Properties | Typical Applications |

|---|---|---|

| Acrylic Resin (AR) | Easy rework, fast drying, good moisture resistance | Consumer electronics, industrial controls |

| Silicone Resin (SR) | Wide temperature range, high flexibility | Automotive, power electronics |

| Urethane Resin (UR) | Excellent chemical and abrasion resistance | Aerospace, military electronics |

| Epoxy Resin (ER) | Hard, durable, high chemical resistance | Harsh industrial environments |

| Parylene | Ultra-uniform, pinhole-free, low dielectric loss | Medical, RF and mmWave PCB |

From a dielectric standpoint, conformal coatings typically provide breakdown strengths of 1.5–7 kV/mil while adding minimal parasitic capacitance. For high-frequency RF PCB and mmWave designs, thin and uniform coatings such as Parylene are preferred to minimize dielectric loading and EMI coupling.

GOPCBA Case Study — Automotive Sensor PCB

Industry Application: Automotive environmental sensor module

Customer Requirements

- Long-term moisture and salt spray resistance

- Stable electrical insulation under bias

- Compatibility with automated selective coating

- Minimal impact on signal integrity

Engineering Challenges Initial field failures revealed corrosion at connector solder joints and leakage current during high-humidity testing. Manual spray coating produced inconsistent coverage and coating bridges.

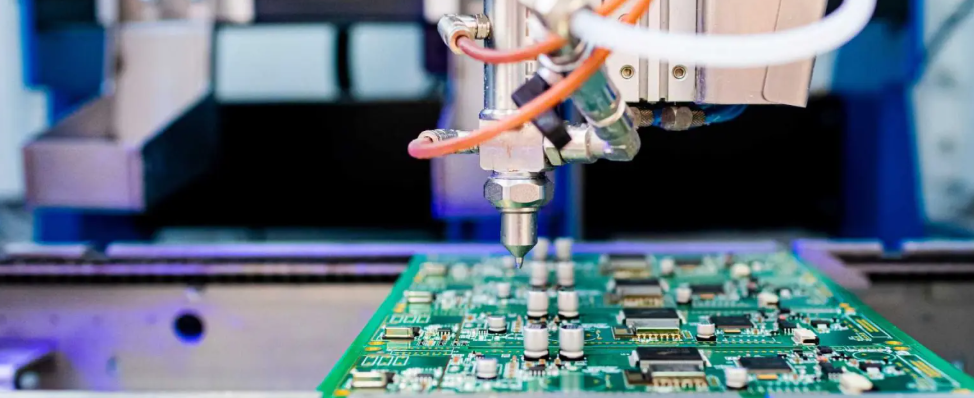

GOPCBA Solution GOPCBA implemented a selective coating process using silicone resin optimized for automotive temperature cycling. Masking was eliminated through robotic path programming, ensuring repeatable thickness and coverage control.

Measured Results

| Test Parameter | Requirement | Measured Result |

| Insulation Resistance (85/85) | ≥100 MΩ | >500 MΩ |

| Salt Spray Exposure | 96 h | No corrosion |

| Coating Thickness | 50–75 μm | 62 μm avg |

| Functional Test Yield | ≥99.5% | 99.9% |

Stackup Design & RF Implementation

Although conformal coating is applied post-assembly, its interaction with PCB stackup and layout must be considered during design. Coating thickness and dielectric constant can influence impedance control, especially in high-speed digital and RF PCB traces.

Coating-Aware PCB Design Guidelines

| Design Aspect | Engineering Consideration |

| Trace Spacing | Allow for coating thickness to prevent bridging |

| Via Tenting | Prevent capillary wicking and void formation |

| Connector Placement | Avoid shadowing during selective coating |

| Ground Areas | Maintain uncoated contact points |

HFSS and ADS simulations are often used to evaluate dielectric loading effects on insertion loss and EMI performance. TDR measurements validate that coated transmission lines remain within impedance tolerance. For power-dense assemblies, Thermal FEM analysis confirms that the coating does not impede heat dissipation.

Environmental & Reliability Validation

Conformal-coated PCBs undergo rigorous qualification testing to verify protection effectiveness under real-world stress conditions.

Reliability Test Summary

| Test Type | Condition | Result |

| Thermal Cycling | -40°C to +125°C, 1000 cycles | Pass |

| Damp Heat | 85°C / 85% RH, 1000 h | Pass |

| Vibration | Automotive vibration profile | Pass |

| Solder Reflow | 260°C, multiple cycles | No delamination |

Proper surface cleanliness prior to coating is essential. Ionic contamination testing and controlled cleaning processes significantly reduce the risk of dewetting, fisheyes, and dendritic growth.

Engineering Summary & Contact

Conformal coating is a mission-critical reliability process that protects PCBs from environmental and electrical stress while enabling higher circuit density and longer service life. When approached as a controlled engineering discipline—integrating material selection, process optimization, and validation testing—conformal coating enhances performance across industrial, automotive, medical, and RF PCB applications.

GOPCBA provides conformal coating process development, selective coating automation, and full reliability validation as part of its PCB assembly services. Engineering teams seeking robust environmental protection solutions are encouraged to consult GOPCBA for coating material selection and process optimization.