Engineering Context

Automotive radar and advanced driver-assistance systems (ADAS) operate in increasingly demanding RF environments, typically at 24 GHz, 77 GHz, and extending toward mmWave sensor fusion platforms. Under-hood and bumper-mounted radar modules are exposed to continuous high-temperature operation, rapid thermal cycling, vibration, and humidity. In such conditions, conventional FR-4 materials struggle to maintain phase stability, insertion loss consistency, and long-term reliability.

Ceramic PCB materials, including alumina-based and ceramic-filled hydrocarbon laminates, have emerged as key enablers for automotive radar PCB and ADAS sensor platforms. This article evaluates phase stability and high-temperature performance of ceramic PCBs from a practical engineering perspective, combining material science, stackup design, electromagnetic simulation, and reliability validation aligned with automotive-grade requirements.

Core Engineering Challenges

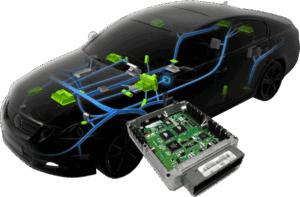

Automotive radar and ADAS sensor platforms introduce several PCB-level engineering challenges that directly impact RF performance and system accuracy.

One major challenge is phase stability. Beamforming accuracy, Doppler resolution, and target angle estimation depend on consistent phase response across temperature and frequency. Even small dielectric constant drift can introduce phase errors in RF PCB transmission lines at mmWave frequencies.

Another challenge is high-temperature endurance. Radar PCBs may experience sustained temperatures above 125 °C, with short-term exposure up to 150 °C during solder reflow or extreme operating conditions. Materials must maintain dielectric stability, low-loss behavior, and mechanical integrity across these ranges.

CTE mismatch and mechanical stress are also critical. Automotive vibration and thermal cycling can induce microcracks, via fatigue, and copper delamination if PCB materials are not well matched to copper and component packages.

Finally, EMI control and insertion loss consistency become more difficult as signal wavelengths shrink. Automotive radar PCB designs require precise impedance matching, stable loss tangent, and predictable lamination behavior to ensure manufacturability and repeatability.

Material Science & Dielectric Performance

Ceramic PCB materials are selected for automotive radar primarily due to their superior dielectric stability and thermal robustness compared with standard organic laminates.

Key Material Characteristics

| Parameter | Ceramic PCB Typical Value | Engineering Impact |

|---|---|---|

| Dielectric Constant (Dk) | 6.0 – 9.8 (stable) | Consistent phase response |

| Dk Temperature Coefficient | ±30 ppm/°C | Low phase drift |

| Dissipation Factor (Df) | ≤0.002 @ 77 GHz | Low insertion loss |

| Glass Transition (Tg) | >300 °C | High thermal margin |

| Thermal Conductivity | 3–8 W/m·K | Improved heat spreading |

| Z-axis CTE | <25 ppm/°C | Via reliability |

Compared with FR-4 or low-cost RF PCB materials, ceramic PCB substrates exhibit minimal dielectric fluctuation under temperature stress. This stability directly translates into reduced phase error in automotive radar signal paths.

From a material science perspective, ceramic fillers suppress molecular polarization changes at elevated temperatures, maintaining dielectric consistency even during long-term high-temperature exposure.

GOPCBA Case Study — Automotive Radar PCB

Customer Background

A Tier-1 automotive supplier developing a 77 GHz automotive radar module for ADAS applications required a PCB solution capable of maintaining phase accuracy across −40 °C to +140 °C operating conditions. The radar PCB integrated RF front-end, antenna array, and control circuitry within a compact multilayer structure.

Engineering Problems

-

Phase drift exceeding ±5° across temperature range

-

Insertion loss variation impacting radar sensitivity

-

Via fatigue observed after thermal cycling

-

EMI coupling between RF and digital control layers

GOPCBA Solution

GOPCBA proposed a ceramic PCB-based stackup optimized for automotive radar applications. The solution focused on controlled dielectric thickness, low-loss copper profiles, and balanced layer symmetry to improve mechanical stability.

Measured Performance Results

| Test Item | Requirement | Measured Result |

|---|---|---|

| Phase Stability (−40 °C to 140 °C) | ≤±3° | ±1.6° |

| Insertion Loss @ 77 GHz | ≤1.2 dB | 0.85 dB |

| Impedance Tolerance | ±5% | ±2.8% |

| EMI Leakage | < −40 dBc | −47 dBc |

The ceramic PCB demonstrated clear advantages in phase stability and RF consistency under automotive conditions.

Stackup Design & RF Implementation

Stackup architecture plays a critical role in achieving stable RF PCB performance for automotive radar.

Example Automotive Radar PCB Stackup

| Layer | Function | Material |

|---|---|---|

| L1 | RF Signal / Antenna | Ceramic PCB |

| L2 | RF Ground | Copper |

| L3 | Control Signals | High-Tg Core |

| L4 | Power Plane | High-Tg Core |

| L5 | RF Ground | Copper |

| L6 | RF Signal | Ceramic PCB |

This hybrid stackup balances cost and performance by using ceramic PCB materials only where RF phase stability is critical, while maintaining robust power integrity and EMI isolation.

Electromagnetic simulation using HFSS and ADS confirmed controlled impedance and minimal phase deviation across operating temperatures. TDR measurements validated impedance consistency after lamination and assembly.

Environmental & Reliability Validation

Automotive-grade ceramic PCB solutions must pass stringent reliability testing to ensure long-term field performance.

Reliability Test Summary

| Test Type | Condition | Result |

|---|---|---|

| Thermal Cycling | −40 °C ↔ 140 °C, 1000 cycles | Pass |

| High-Temp Storage | 150 °C, 1000 hrs | Pass |

| Humidity Bias | 85 °C / 85% RH, 1000 hrs | Pass |

| Vibration | Automotive standard | Pass |

| Solder Reflow | 3× @ 260 °C | No delamination |

Thermal FEM analysis confirmed uniform heat distribution across the ceramic PCB, reducing localized stress concentration around vias and RF components.

These results demonstrate that ceramic PCB materials provide a robust platform for automotive radar and ADAS sensor reliability under combined thermal, mechanical, and environmental stress.

Engineering Summary & Contact

Ceramic PCB technology offers a compelling solution for automotive radar and ADAS sensor platforms where phase stability, high-temperature endurance, and RF reliability are non-negotiable requirements. Through controlled dielectric behavior, low-loss performance, and superior thermal stability, ceramic PCBs enable consistent mmWave radar operation across harsh automotive environments.

From material selection and stackup design to simulation and reliability validation, an engineering-driven approach is essential to fully realize the benefits of ceramic PCB solutions in automotive radar applications.

For further discussion on automotive radar PCB material selection, stackup optimization, and RF validation support, GOPCBA engineering teams provide technical consultation and prototype manufacturing services tailored to ADAS and automotive RF systems.