Abstract

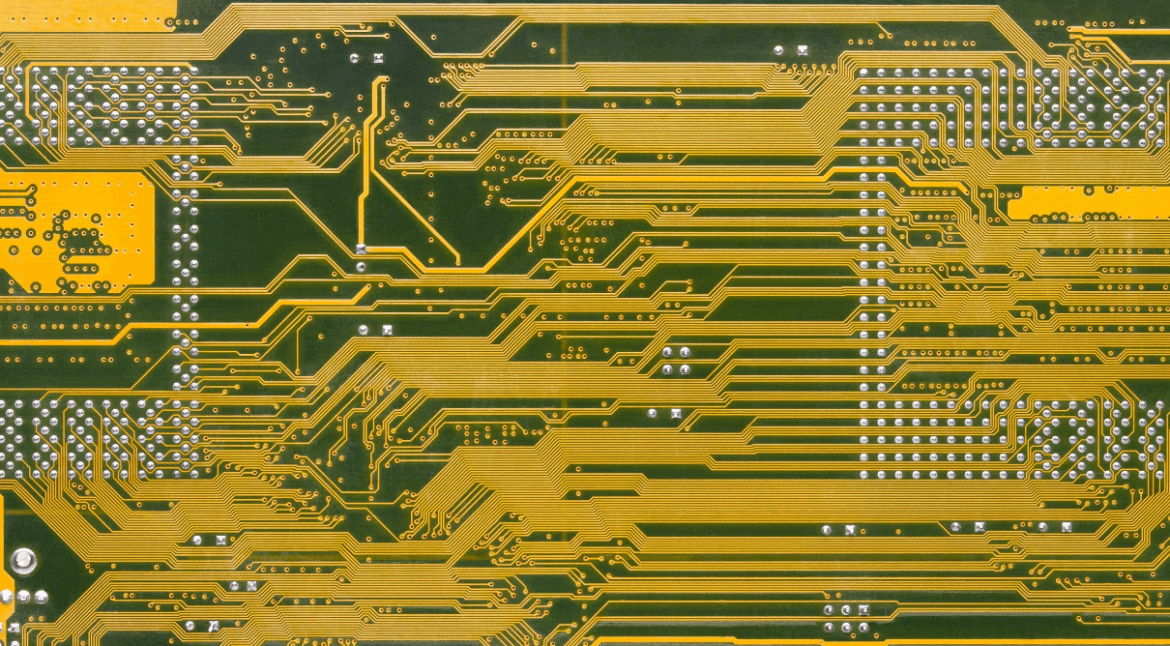

Factory automation control systems form the backbone of modern manufacturing, enabling precise motion control, real-time monitoring, and deterministic communication across complex industrial environments. At the core of these systems lies the industrial PCB assembly, which integrates processors, power electronics, communication interfaces, and sensor inputs into a platform expected to operate continuously under electrical noise, vibration, and thermal stress.

Unlike consumer electronics, industrial PCB assembly must prioritize reliability, repeatability, and process precision over cost-driven miniaturization. Assembly-related variables—such as solder joint geometry, via integrity, component placement accuracy, and thermal profile control—directly influence system uptime and lifecycle cost. This article examines how an engineering-driven approach to industrial PCB assembly enhances reliability and manufacturing precision in factory automation control systems, combining material science, stackup design, simulation, and environmental validation.

Core Engineering Challenges

Industrial automation environments introduce challenges that place exceptional demands on PCB assembly quality.

Continuous operation and lifecycle expectations are among the most critical requirements. Factory automation control systems often run 24/7 for years, with limited opportunities for maintenance. Even minor assembly defects can evolve into intermittent failures that disrupt production lines and cause significant downtime.

Electrical noise and EMI exposure present another challenge. Variable-frequency drives, motors, relays, and switching power supplies generate substantial electromagnetic interference. Industrial PCB assemblies must maintain stable signal and power integrity despite these hostile electrical conditions.

Mechanical stress and vibration are unavoidable in factory settings. Conveyor systems, robotic arms, and heavy machinery introduce constant vibration that can fatigue solder joints, vias, and component leads if assembly processes are not tightly controlled.

Finally, process consistency across production batches is essential. Factory automation OEMs require predictable performance across long production runs. Variability in soldering, placement accuracy, or thermal processing can lead to inconsistent field behavior, complicating qualification and maintenance strategies.

Material Science & Dielectric Performance

Although industrial PCB assembly is primarily a manufacturing discipline, material science plays a foundational role in enabling reliable and precise assembly outcomes.

High-Tg FR-4 materials are commonly selected for factory automation PCBs due to their balanced mechanical strength, thermal stability, and cost efficiency. In designs involving high-speed industrial Ethernet or fieldbus communication, controlled dielectric behavior becomes increasingly important to preserve signal integrity.

Typical Material Characteristics for Industrial PCB Assembly

| Parameter | Typical Industrial Value | Engineering Impact |

|---|---|---|

| Dielectric Constant (Dk) | 3.8 – 4.4 | Predictable signal timing |

| Dissipation Factor (Df) | ≤0.015 | Reduced signal loss |

| Glass Transition (Tg) | ≥170 °C | Reflow and thermal margin |

| Z-axis CTE | ≤70 ppm/°C | Via and solder joint reliability |

| Copper Thickness | 1–2 oz | Power handling and durability |

Stable dielectric performance supports consistent impedance in communication traces, while controlled CTE behavior minimizes stress accumulation during thermal cycling and assembly rework. Surface finishes such as ENIG or ENEPIG are often selected to ensure uniform solderability and long-term contact reliability.

GOPCBA Case Study — Factory Automation Control PCB

Customer Background

A manufacturer of factory automation control systems required an industrial PCB assembly for a modular PLC and motion control platform. The PCB integrated microcontrollers, industrial Ethernet interfaces, isolated I/O channels, and power regulation circuitry, designed for continuous operation in electrically noisy factory environments.

Engineering Problems

-

Intermittent failures traced to solder joint fatigue near connectors

-

EMI coupling affecting high-speed industrial Ethernet links

-

Assembly yield variation across different production lots

-

Thermal stress near power components reducing long-term reliability

GOPCBA Solution

GOPCBA implemented an engineering-driven industrial PCB assembly solution emphasizing process precision and reliability. Key actions included refined stencil design for consistent solder volume, optimized reflow profiles matched to laminate Tg and copper distribution, and reinforced via plating for mechanically stressed connectors.

Component placement strategies were adjusted to improve grounding continuity and reduce EMI coupling. Design-for-assembly reviews addressed pad geometry and hole-to-lead ratios to improve solder fillet formation and mechanical strength.

Measured Performance Results

| Test Item | Requirement | Measured Result |

|---|---|---|

| Assembly Yield | ≥98% | 99.5% |

| Solder Joint Defect Rate | ≤0.5% | 0.16% |

| Ethernet BER | ≤10⁻¹² | <10⁻¹⁴ |

| Thermal Hotspot Reduction | Target ≥20% | 34% |

The optimized industrial PCB assembly demonstrated improved electrical stability and mechanical robustness under simulated factory conditions.

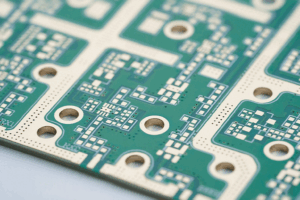

Stackup Design & RF Implementation

Stackup design strongly influences the success of industrial PCB assembly by affecting impedance control, EMI suppression, and thermal behavior during soldering.

Example Stackup for Factory Automation PCB

| Layer | Function | Material |

|---|---|---|

| L1 | Components / High-Speed Signals | High-Tg FR-4 |

| L2 | Solid Ground Plane | Copper |

| L3 | Power Plane | Copper |

| L4 | Control and I/O Signals | High-Tg FR-4 |

| L5 | Ground Plane | Copper |

| L6 | Bottom Components / Low-Speed Signals | High-Tg FR-4 |

This stackup provides short return paths for high-speed signals and effective isolation between noisy power circuits and sensitive control interfaces. Balanced copper distribution minimizes warpage during reflow, supporting precise component placement and consistent solder joint formation.

Signal integrity simulations using ADS and impedance verification via TDR measurements confirmed stable transmission characteristics after assembly. Power integrity analysis ensured that transient loads from I/O switching did not induce excessive voltage ripple.

Environmental & Reliability Validation

Industrial PCB assemblies for factory automation must undergo rigorous validation to ensure long-term performance in harsh operating conditions.

Reliability Test Summary

| Test Type | Condition | Result |

|---|---|---|

| Thermal Cycling | −40 °C ↔ 85 °C, 500 cycles | Pass |

| High-Temp Operating Life | 85 °C, 1000 hrs | Pass |

| Humidity Exposure | 85 °C / 85% RH | Pass |

| Vibration | Industrial profile | Pass |

| Solder Reflow Endurance | Multiple profiles | No degradation |

Thermal FEM analysis demonstrated uniform heat distribution around power regulators and isolation components, reducing localized stress on solder joints. Post-test cross-section analysis confirmed stable via barrels and intact intermetallic layers.

These validation results confirm that process-precise industrial PCB assembly can maintain electrical and mechanical integrity throughout extended factory operation.

Engineering Summary & Contact

Enhancing reliability and process precision in industrial PCB assembly is essential for factory automation control systems that demand continuous operation, electrical robustness, and predictable performance. By integrating material understanding, optimized stackup design, controlled assembly processes, and comprehensive validation, industrial PCB assemblies can achieve high yield, long service life, and consistent field behavior.

An engineering-driven approach to industrial PCB assembly reduces failure risk, simplifies qualification, and supports scalable manufacturing for factory automation platforms. GOPCBA provides industrial PCB assembly services focused on precision manufacturing, reliability validation, and process consistency to support advanced factory automation control systems across demanding industrial environments.