Engineering Context

Power control electronics are core subsystems in industrial automation, motor drives, power supplies, energy conversion systems, and intelligent control platforms. These products integrate high-current switching devices, power management ICs, control processors, and communication interfaces on compact printed circuit boards. As power density increases, thermal stress and solder joint reliability become decisive factors affecting system stability and service life.

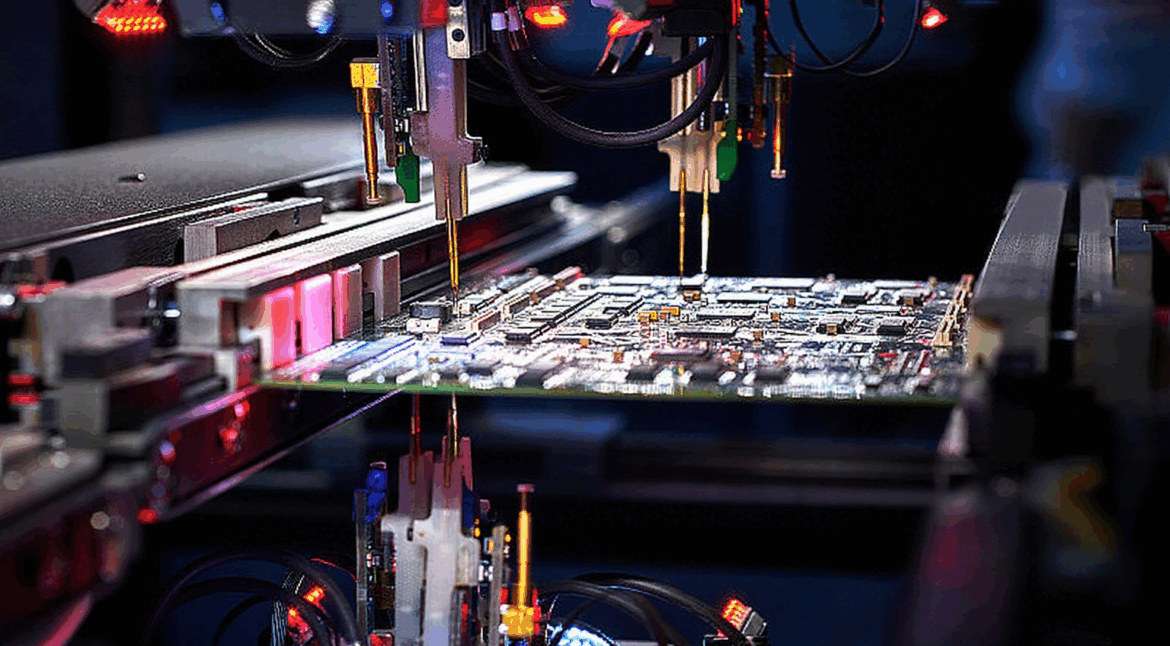

In this context, SMT PCB assembly plays a critical engineering role. Beyond component placement, assembly processes directly influence heat dissipation paths, solder joint integrity, mechanical stress distribution, and long-term electrical performance. Inadequate thermal management or inconsistent solder joints can lead to premature failures, intermittent faults, and degraded power integrity.

This article analyzes how optimized SMT PCB assembly enhances thermal management and solder joint reliability in power control electronics, combining material science, stackup design, assembly process control, and environmental validation to achieve stable and repeatable performance.

Core Engineering Challenges

Power control electronics impose combined electrical, thermal, and mechanical stresses on SMT PCB assemblies.

High power density devices such as MOSFETs, IGBTs, and DC-DC converters generate significant localized heat. If thermal paths from the junction to ambient are poorly designed or inconsistently assembled, temperature gradients increase, accelerating solder fatigue and material degradation.

Solder joint reliability is another critical challenge. Large thermal mass components and uneven copper distribution can cause non-uniform heating during reflow, leading to voids, insufficient wetting, or residual stress in solder joints. These defects may not cause immediate failure but can propagate under thermal cycling.

Power integrity and EMI issues further complicate assembly. High di/dt switching currents can induce noise and voltage ripple, while unstable grounding or power plane connections introduced during assembly can increase electromagnetic emissions.

Manufacturing repeatability is essential, as power control products often operate continuously in industrial environments for many years. Small variations in assembly quality can result in large differences in field reliability.

Material Science & Dielectric Performance

Material selection is foundational for thermal stability and solder joint reliability in SMT PCB assembly for power control electronics.

High-Tg FR-4 and thermally enhanced laminates are commonly used to withstand elevated operating temperatures and repeated thermal cycling. Stable dielectric properties reduce impedance variation in control and feedback circuits, while low Z-axis CTE improves via and solder joint reliability.

Copper thickness and distribution significantly influence thermal performance. Thicker copper planes improve heat spreading and reduce localized hotspots, but also increase thermal mass, requiring carefully optimized reflow profiles.

Material Properties Relevant to Power Control SMT Assembly

| Parameter | Typical Value | Engineering Impact |

|---|---|---|

| Glass Transition Temperature (Tg) | ≥170 °C | Thermal endurance |

| Z-axis CTE | ≤60 ppm/°C | Via & solder reliability |

| Copper Thickness | 1–3 oz | Heat spreading |

| Dielectric Stability | High | Control circuit accuracy |

| Thermal Conductivity | Enhanced | Lower junction temperature |

Material consistency ensures that solder joints and vias maintain structural integrity throughout the product lifecycle.

GOPCBA Case Study — Power Control Electronics PCB

Customer Background

A manufacturer of industrial power control electronics required SMT PCB assembly for a motor drive control board used in factory automation equipment. The board integrated high-current power stages, gate drivers, control processors, and communication interfaces.

Engineering Problems

-

Excessive component temperatures during full-load operation

-

Solder joint cracking observed after thermal cycling tests

-

Voiding under power MOSFET pads

-

Yield loss due to inconsistent reflow behavior

GOPCBA Assembly Solution

GOPCBA implemented a thermally optimized SMT PCB assembly strategy. Power device footprints were reviewed to improve solder paste aperture design, ensuring uniform solder thickness and reduced void formation.

Reflow profiles were customized to balance thermal mass differences between power components and control ICs. Controlled heating and cooling rates minimized residual stress in solder joints.

Additional thermal vias and copper planes were incorporated to enhance heat dissipation. Assembly inspection combined AOI and X-ray analysis to verify solder joint integrity under large thermal pads.

Measured Performance Results

| Parameter | Requirement | Measured Result |

|---|---|---|

| Junction Temperature Reduction | ≥10% | 18% |

| Solder Void Ratio | ≤25% | 11% |

| Thermal Cycling Pass Rate | 100% | 100% |

| SMT Defect Rate | ≤0.5% | 0.18% |

| Assembly Yield | ≥98% | 99.4% |

Stackup Design & RF Implementation

Stackup design directly affects both thermal performance and assembly stability in power control electronics.

Representative Stackup Structure

| Layer | Function |

|---|---|

| L1 | Power Components & Control Signals |

| L2 | Solid Ground Plane |

| L3 | Power Plane (Thick Copper) |

| L4 | Control and Feedback Signals |

| L5 | Ground Plane |

| L6 | Auxiliary Signals / Components |

This structure provides continuous thermal and electrical paths while maintaining mechanical symmetry. Dedicated ground planes improve EMI suppression, while thick copper power planes enhance heat spreading from high-power devices.

Thermal FEM simulations validated heat flow paths and identified hotspots. TDR and power integrity analysis confirmed stable impedance and low voltage ripple after assembly.

Environmental & Reliability Validation

Reliability validation ensures that SMT PCB assemblies for power control electronics can withstand harsh operating conditions.

Thermal cycling tests simulate repeated power on/off conditions, stressing solder joints and vias. High-temperature operating life tests evaluate long-term material stability and solder joint endurance.

Humidity exposure and vibration tests assess mechanical robustness in industrial environments. Solder reflow endurance verifies resistance to potential rework cycles.

Reliability Test Summary

| Test Type | Condition | Result |

|---|---|---|

| Thermal Cycling | −40 °C ↔ +125 °C, 1000 cycles | Pass |

| High-Temp Operating Life | 125 °C, 1000 hrs | Pass |

| Damp Heat | 85 °C / 85% RH | Pass |

| Vibration | Industrial profile | Pass |

| Reflow Endurance | 3 cycles | No degradation |

Post-test electrical measurements confirmed stable power integrity and unchanged thermal performance.

Engineering Summary & Contact

Enhancing thermal management and solder joint reliability is essential for SMT PCB assembly in power control electronics, where high power density and long service life are mandatory requirements. By integrating appropriate materials, optimized stackup design, precise assembly processes, and rigorous reliability validation, thermal stress and solder fatigue can be effectively mitigated.

GOPCBA provides engineering-driven SMT PCB assembly solutions focused on thermal optimization, solder joint integrity, and repeatable manufacturing quality for power control electronics and industrial power systems. For DFM review, thermal analysis, or SMT assembly support, contact GOPCBA to discuss your power electronics project requirements.