In electronic product development, PCB (Printed Circuit Board) prototyping is a crucial step that turns design concepts into functional hardware. As hardware development cycles continue to accelerate, fast PCB prototyping stations have become the preferred choice for engineers, hardware startups, and research institutions.

So, what exactly is a fast PCB prototyping station? Why is it so important? And how can you choose the right one? Let’s explore these questions in detail.

1. What Is a Fast PCB Prototyping Station?

A fast PCB prototyping station is a service platform designed to quickly complete PCB fabrication, testing, and delivery. Compared with traditional PCB manufacturers, these platforms focus on speed, precision, and convenience, making them ideal for:

-

Circuit testing and validation during product development

-

Small-batch custom PCB production

-

Rapid iteration in hardware innovation projects

In short, a fast PCB prototyping service helps engineers transform PCB designs into physical boards quickly and efficiently.

2. Why Choose Fast PCB Prototyping?

In today’s electronics industry, speed is everything. Choosing a fast PCB prototyping station offers several key advantages:

1. Shorter Development Cycles

Traditional PCB fabrication might take up to 7 days or more. Fast PCB prototyping services, however, can deliver boards within 24 hours, dramatically accelerating design validation and iteration.

2. Lower Trial-and-Error Costs

During the prototyping phase, you can produce small quantities for testing before mass production. This reduces the risk of large financial losses caused by design errors.

3. Easy Online Ordering

Most modern prototyping platforms support online Gerber file uploads, instant quotes, and automated design checks, allowing the entire process to run smoothly without manual intervention.

4. Support for Complex PCB Designs

High-quality PCB prototyping stations support HDI (High-Density Interconnect), multi-layer boards, and flexible PCBs (FPC)—perfect for complex or high-performance designs.

3. Core Services of Fast PCB Prototyping Stations

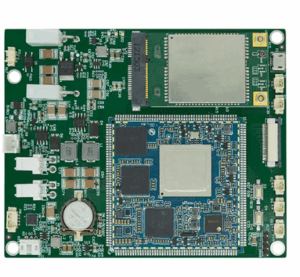

A professional PCB prototyping service typically provides the following:

| Service | Description |

|---|---|

| PCB Fabrication | Rapid production from single-layer to multi-layer boards |

| SMT Assembly | Small-batch component placement and soldering |

| Design Rule Checking (DRC) | Automated design verification for errors |

| Express Production | 12-hour or 24-hour rush delivery options |

| Material Selection | FR-4, aluminum substrate, flexible PCB, and more |

4. How to Choose the Right Fast PCB Prototyping Platform

When selecting a prototyping service, consider the following key factors:

-

Turnaround Time and Reliability – Check if they offer 24-hour delivery and consistent on-time performance.

-

Quality Certifications – Prefer manufacturers with ISO9001 and UL certifications.

-

User Experience – Ensure they support automatic quotes, file checking, and order tracking.

-

Customer Feedback – Look for engineer recommendations and verified user reviews.

5. Conclusion: Fast PCB Prototyping Accelerates Innovation

For hardware engineers and developers, fast PCB prototyping is more than just a manufacturing upgrade—it’s an innovation enabler.

It allows teams to test faster, iterate faster, and launch faster, giving them a significant competitive edge.

As automation and smart manufacturing continue to advance, fast PCB prototyping stations will play an increasingly vital role in the electronics industry.