Heat dissipation is a critical challenge in modern PCB design. Excessive temperatures can degrade component performance, reduce reliability, and shorten product lifespan. This guide explores seven actionable strategies to optimize PCB thermal management, incorporating heat sinks, thermal vias, copper utilization, and layout best practices to achieve efficient cooling. 1. Heat Sinks & Thermal Pads…

In modern high-density electronics, the most critical threats to reliability are often invisible. A microscopic solder defect, hidden beneath a complex BGA package or too subtle for the human eye, can lead to intermittent failures or catastrophic breakdowns in the field. This is why “good enough” visual inspection is no…

In the world of Printed Circuit Board Assembly (PCBA), soldering is the crucial process that brings a design to life. But not all soldering methods are created equal. The two dominant automated technologies, Reflow Soldering and Wave Soldering, serve very different purposes and are engineered for different types of components.…

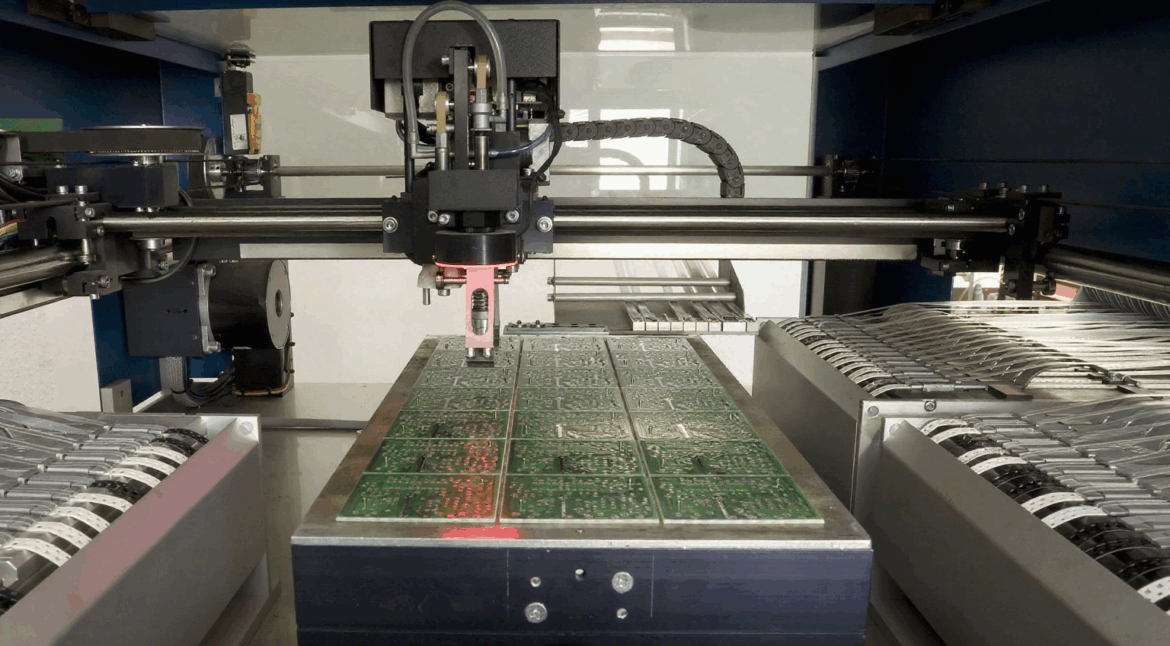

Have you ever wondered how a simple, bare circuit board is transformed into the complex electronic “brain” that powers your favorite devices? The magic behind this transformation is a highly automated and incredibly precise process known as Surface-Mount Technology (SMT) Assembly. It’s a symphony of robotics, chemistry, and meticulous process…

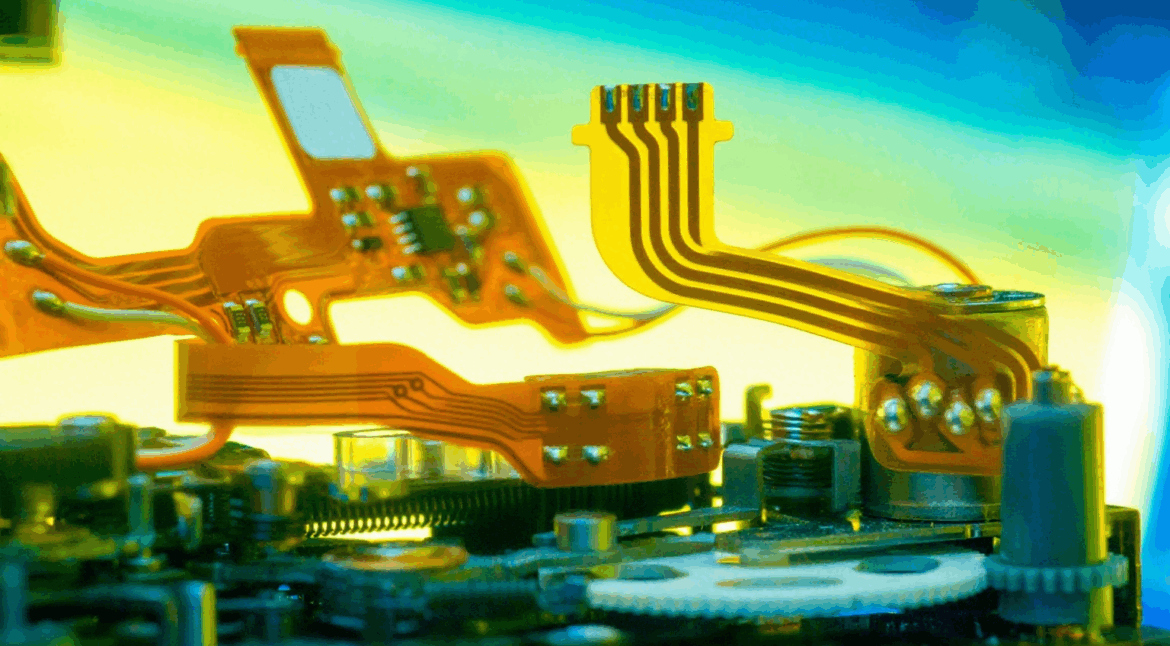

In today’s relentless drive for smaller, lighter, and more powerful devices, traditional flat circuit boards are no longer enough. As products evolve, designers need innovative solutions to overcome the physical constraints of rigid PCBs. This is where Flexible PCBs (FPC) and Rigid-Flex PCBs play a transformative role, enabling engineers to…

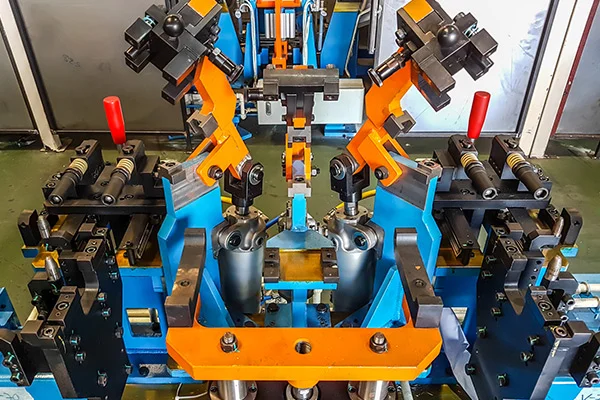

On modern automated electronics manufacturing lines, every flawless printed circuit board assembly (PCBA) is supported by a group of unseen “behind-the-scenes heroes” — jigs and fixtures. They may not attract as much attention as high-speed pick-and-place machines, but they are an indispensable bridge between design and large-scale, high-quality production. Today,…

In the world of modern electronics manufacturing, the quality of every solder joint is directly linked to the performance and lifespan of the final product. Especially for printed circuit board assemblies (PCBA) with increasingly precise components and complex layouts, the soldering process has gone far beyond a simple “connection” and…

High Density Interconnect (HDI) technology has revolutionized PCB (Printed Circuit Board) design, enabling compact, high-performance electronics. From smartphones and tablets to automotive radar and aerospace systems, HDI PCBs make it possible to fit more functionality into smaller footprints without compromising speed or reliability. Central to this technology are microvias, blind…

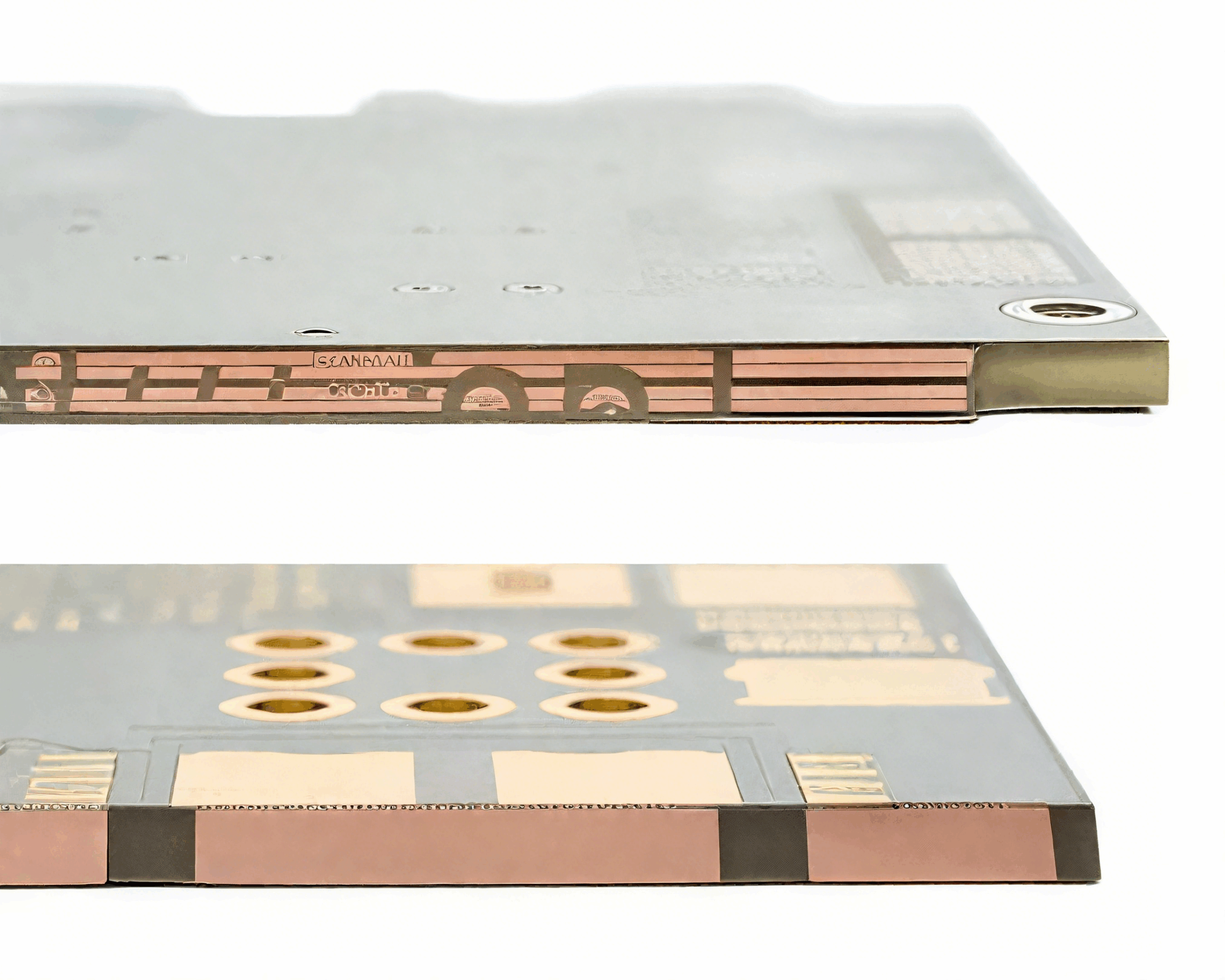

In the electronics industry, PCB (Printed Circuit Board) technology has evolved dramatically — from simple single-sided boards to today’s complex 10, 20, or even higher-layer constructions. This progress enables faster signal processing and higher-density packaging, but it also brings major challenges in the multilayer lamination process, which is critical to…

In the fast-evolving world of electronics, performance and reliability are paramount. High-power applications, such as power supplies, electric vehicles, industrial machinery, and RF amplifiers, place extreme demands on printed circuit boards (PCBs). Traditional PCBs often struggle to cope with these requirements, which is where heavy copper PCBs come into play.…