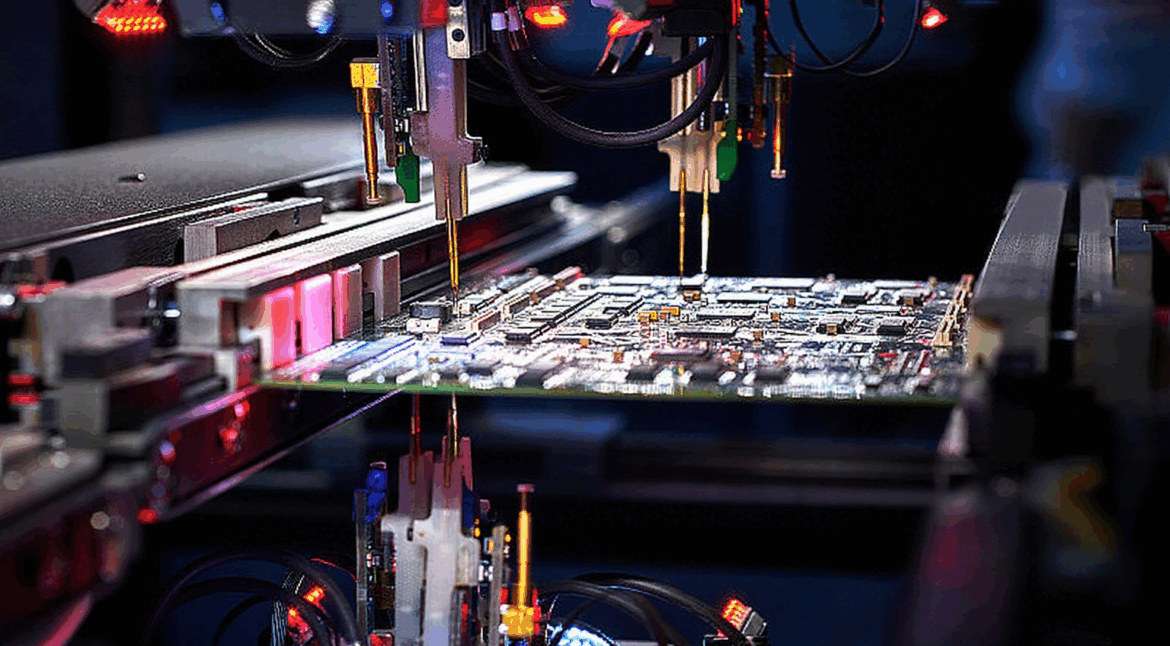

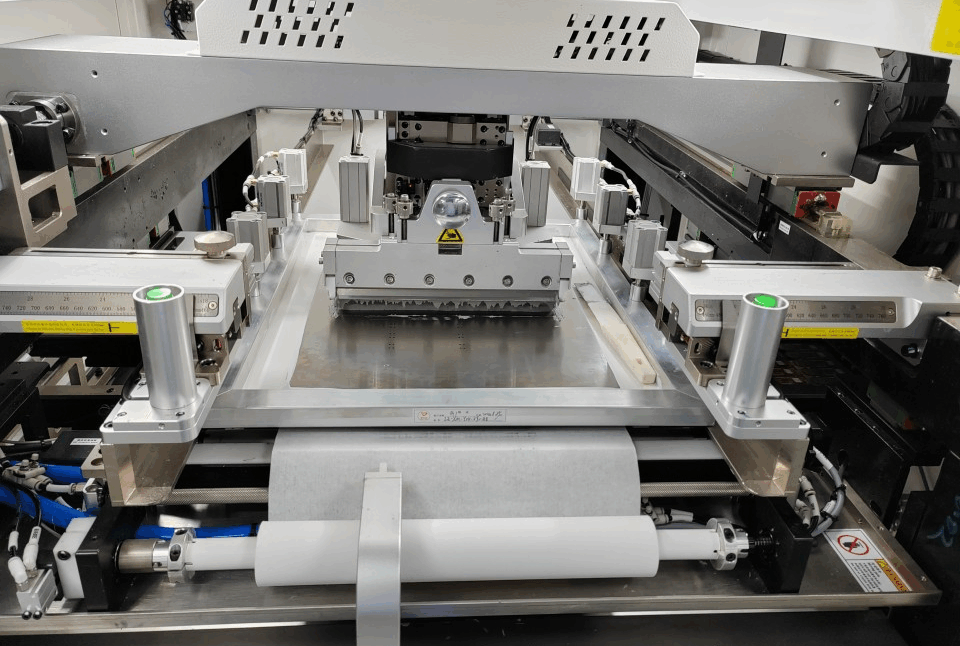

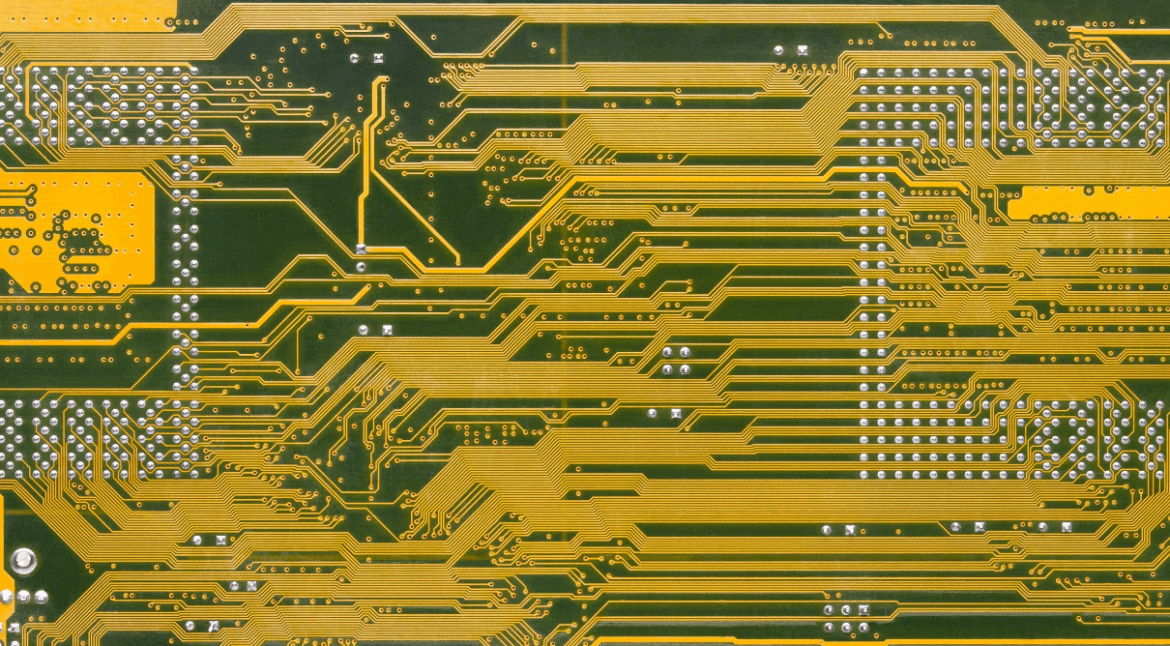

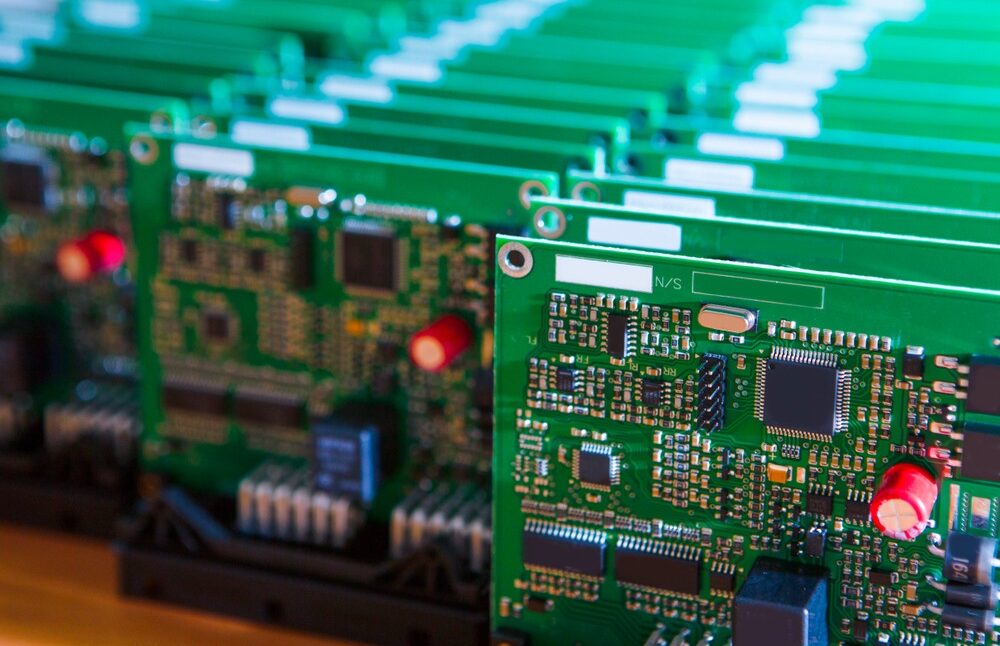

Engineering Context Power control electronics are core subsystems in industrial automation, motor drives, power supplies, energy conversion systems, and intelligent control platforms. These products integrate high-current switching devices, power management ICs, control processors, and communication interfaces on compact printed circuit boards. As power density increases, thermal stress and solder joint…

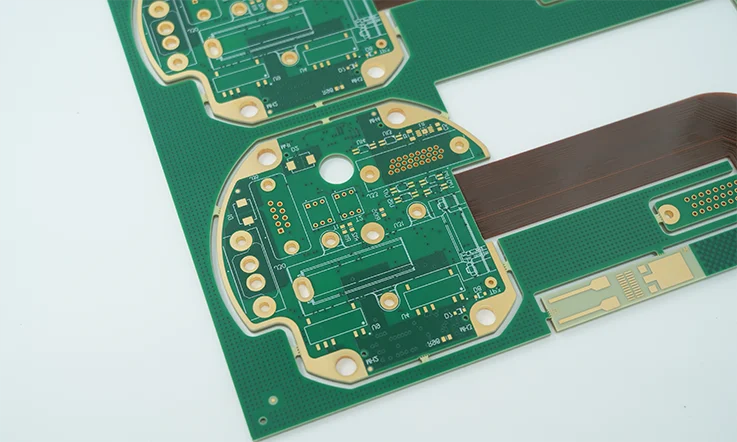

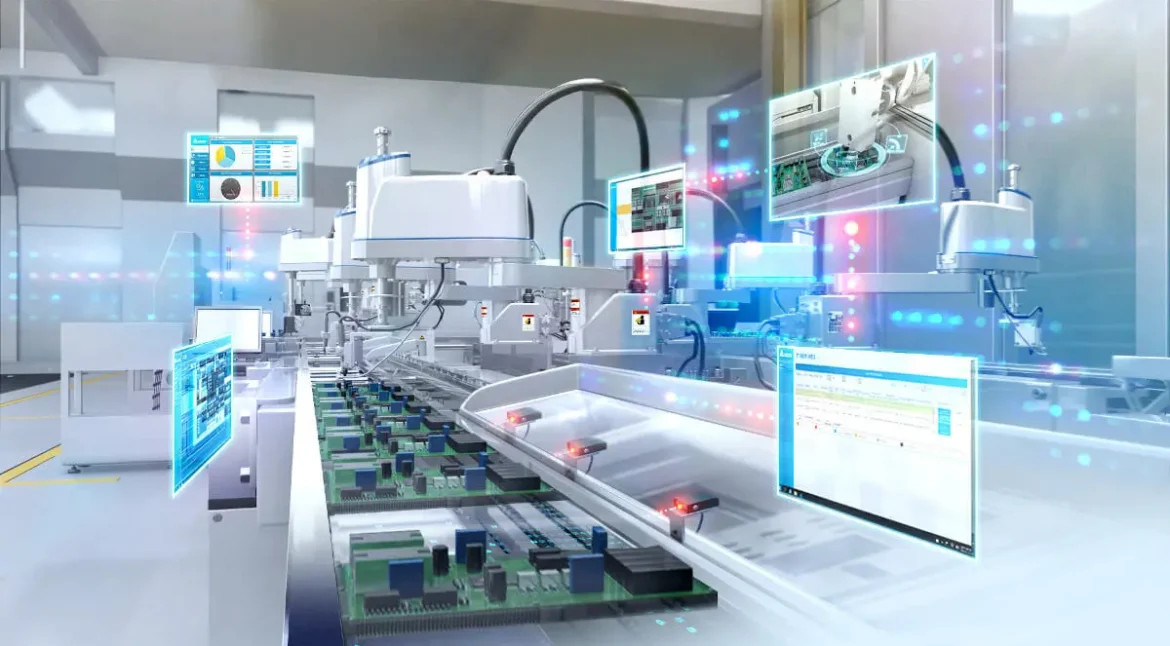

Engineering Context High-speed communication modules are fundamental components in modern networking equipment, data transmission systems, and industrial communication platforms. These modules integrate high-speed processors, RF interfaces, power management circuits, and dense interconnect structures within compact form factors. In such architectures, SMT PCB assembly is no longer a purely mechanical manufacturing…

Engineering Context Industrial communication equipment forms the backbone of modern factory automation, distributed control systems, and industrial IoT networks. From Ethernet-based fieldbus modules and industrial gateways to PLC communication cards and edge controllers, these systems rely on stable signal transmission and consistent manufacturing quality to ensure uninterrupted operation in electrically…

Engineering Context Industrial electronic systems are increasingly deployed in environments characterized by high temperature gradients, continuous vibration, humidity exposure, electrical noise, and long service lifecycles. Factory automation controllers, industrial gateways, motor drives, and field-deployed sensing units demand industrial PCB assembly processes that prioritize assembly precision, electrical stability, and lifecycle reliability…

Engineering Context Industrial IoT gateways serve as the critical interface between field-level sensors, industrial networks, and cloud-based analytics platforms. These gateways integrate multiple communication technologies, including industrial Ethernet, wireless interfaces, and fieldbus protocols, within compact enclosures deployed in electrically noisy and environmentally harsh industrial environments. The industrial PCB assembly used…

Engineering Context Motor drive systems and programmable logic controller (PLC) platforms are core elements of modern industrial automation, responsible for precise motion control, deterministic logic execution, and continuous system operation. The industrial PCB assembly used in these platforms must withstand high current transients, electrical noise, vibration, and long-term thermal stress…

Abstract Factory automation control systems form the backbone of modern manufacturing, enabling precise motion control, real-time monitoring, and deterministic communication across complex industrial environments. At the core of these systems lies the industrial PCB assembly, which integrates processors, power electronics, communication interfaces, and sensor inputs into a platform expected to…

Engineering Context PCB assembly services form the critical bridge between electronic design intent and reliable product realization. As electronic systems evolve toward higher integration, higher frequencies, and stricter reliability requirements, PCB assembly is no longer a purely manufacturing task but an engineering-controlled process that directly impacts electrical performance, thermal behavior,…

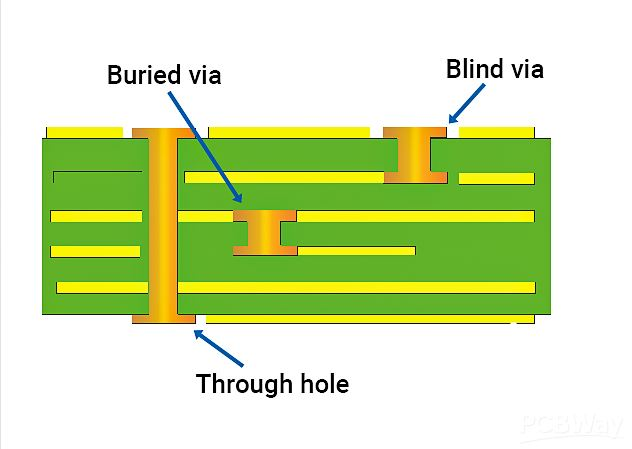

Engineering Context / Abstract Through-hole PCB assembly (THT assembly) remains a critical manufacturing technology for electronics that demand superior mechanical strength, high current capability, and long-term reliability. While surface-mount technology dominates high-density consumer electronics, through-hole PCB assembly continues to be indispensable in industrial controls, medical equipment, power electronics, automotive modules,…

Engineering Context Medical ventilators are life-critical devices that must operate continuously, accurately, and safely under strict regulatory and environmental constraints. At the core of these systems lies the medical ventilator PCB assembly, which integrates power management, sensor interfaces, control processors, communication modules, and alarm systems into a compact and highly…